Type of industries

- Paint

- Printing

- Chemical

- Laboratories

- Automotive

- Mecanical

- Big industries…

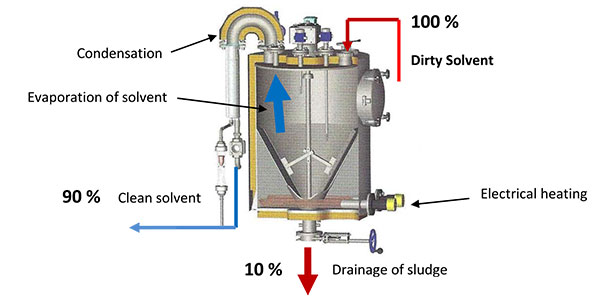

The distillation units of the German constructor OFRU allow to easily recover polluted solvent with very low energy.

The return on investment is very quick and allow a lowering of the necessary purchase of solvent and assuring a constant quality of solvent.

The successful medium range of OFRU proposes a heating with integrated steam generator under vacuum.

The machines are built in stainless steel, to resist to aggressive solvents.

The range of distillation units of OFRU is actually the biggest and the most modern in the world.

We also have a smaller range and a much bigger range for important production.

OFRU is a German manufactory, near Frankfurt, with a climbing impact in the world.

A list of some of them will better illustrate their impact on the word’s market

The priority that this German factory choosed to build their machines is for sure the reason of their growing success.

Safety first

Product benefits

- Product-affected parts in stainless steel : this enables to resist to the most aggressive solvents

- Automatic and continuous feeding with dirty solvents

- Filling level is kept constant. Plant distills always further, no batch operation

- Conical distillation vessel in stainless steel AISI 304 with lathe and plain surface: Easy and complete drainage of vessel content by natural gravity and scraper support

- Perfect scraper system: Blades keep free the evaporator walls from settlements, no re-adjustment necessary, guarantee an optimal and real cleaning effect

- Water cooling: Optimal condensation of solvent vapors, even at high ambient temperature

- Electric panel with SIEMENS digital control inside

- Automatic operation

- Auto-stop: When dirty solvent drum is empty, when over temperature, when no thermal heating media existent, when no cooling water flow

- Constructed according to latest EU directives: High levels of operational safety

Integrated modern steam heater in place of usual diathermic oil heating

- Solvent is heated up faster than with conventional thermal oil heating systems

- No oil change necessary = saves money and maintenance

- No incrustation of heating elements any more, always constant heating power

- No oil sludge in the machine

- Closed system: No corrosion of vessel because of air moisture