Type of industries

- Paint

- Pharmaceutical

- Chemical

- Aeronautical

- Auto

- Mechanical

- Recycling

- And so on…

Purpose

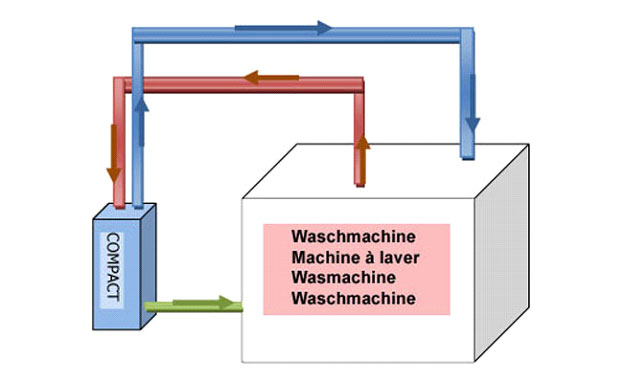

The system, called “CRYOCLEAN COMPACT”, allows to treat all the polluted air coming, either from the production site, either from a wash machine: the process happen in closed air circuit.

By modifying rather abruptly the temperature while preserving an equal charge, it causes a condensation of part of the solvent which will be then recovered and given at disposal of the production or sent back inside the wash machine, all this occurring in closed circuit.

No emission anymore in the air and a complete recovery of solvent during the drying cycle.

Again a place in the production where many economies are to be realized.

Washings of parts represent a very important cost in the production.

A really attractive investment, as we know that, during every drying cycle of a wash machine, +- 25 liter of solvent are thrown in the air or are burned.

It seems not much, but when we tell on 10 cyclus a day, on 220 days, we are speaking about … 55.000 liter of solvent !! That means …about 55.000 to 60.000€/year lost.

The advantages are numerous

- We are recovering all the solvent thrown out.

- No need of chimney anymore, as we are working in closed air circuit: you can now install your machine where you want

- As we are condensing the humidity of the air, dried air is used during the drying cyclus of the washmachine: this means that the drying cycle will be shorter

- The parts are not wet with solvent anymore, as dried air has been used

- The smelt of solvent when opening the door has nearly disappeared

- Very poor energy consumption

- Easy to mount

- Full automatic system, coordinated with wash machine instructions

- Easy to use, as the Siemens PLC is coordinating everything

If the solvent was originally burned, this system makes it sometimes possible to decrease the dimensioning of the burner.

This same system is applicable for dehumidification and purification of air charged with solvent in robotized productions. (painting rooms and so on…)