There are many different types of hydrocarbons and floating waste, therefore collection equipment must be capable of working quickly and in difficult conditions.

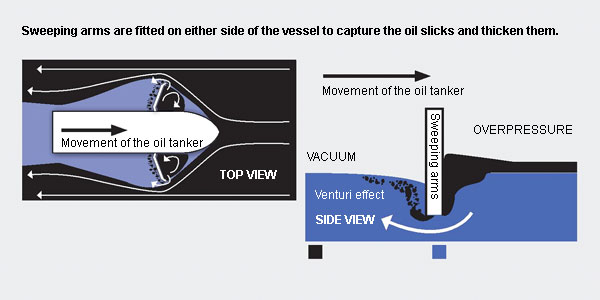

Standard system used currently: Sweeping arms

Top view: The water in front of the arms acts as a mass and diverts the flow towards the end of the arms, creating an acceleration and a Venturi effect, which diverts the hydrocarbons to the outside of the arms.

Cross-section: the hydrocarbons trapped between the arms undergo an overpressure/vacuum effect. A current is generated, which sucks the hydrocarbons from the surface below the sweeping arms.

Disadvantages

These two factors limit the speed of the vessels to 1 knot, restricting their use to maximum wind speeds of Force 3.

The thin layer of hydrocarbons trapped by the arms mixes with water during pumping, creating an emulsion (mayonnaise) which requires treatment in a hopper prior to storage.

The EFINOR SEA CLEANER solution

Working speed increased four-fold – Operation in rough seas (Force 6)

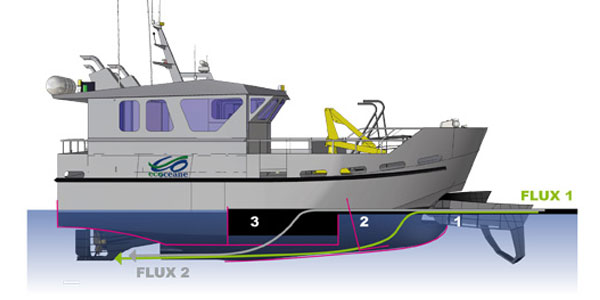

The self-floating arms are connected to the boat by a rotating shaft, which enables them to ride the waves independently of the boat

- All of the surface pollutants trapped by the arms (1 )are aspirated into the boat

- Our system is capable of operating at 4 knots in winds of up to Force 6

- At this speed, the Efinor Sea Cleaner boat can be followed by a supply vessel or oil tanker to which it can transfer the recovered hydrocarbons on a constant basis

How does it work?

A turbine pulls a stream of water through a chamber equipped with a mesh (2) that filters out all solid waste.

From the chamber, the flow is separated into two parts:

Flow 1 : The turbine pumps away the clean water.

Flow 2 : Surface water, polluted with oil and hydrocarbon is channeled into a separator (3) where the hydrocarbons are stored, floating on the water. No emulsion forms, and the hydrocarbon are transferred immediately to a tanker

Stress-free collection

Our patented system does not create emulsion

No treatment before storage

Surface area cleaned in 1 hour

4 knots x 1,852 m x 5 m(9) ≥ 35,000m2 to 60,000m2, equivalent to 80 to 150m3 per hour