For the Industrial Washmachines, pls clik here

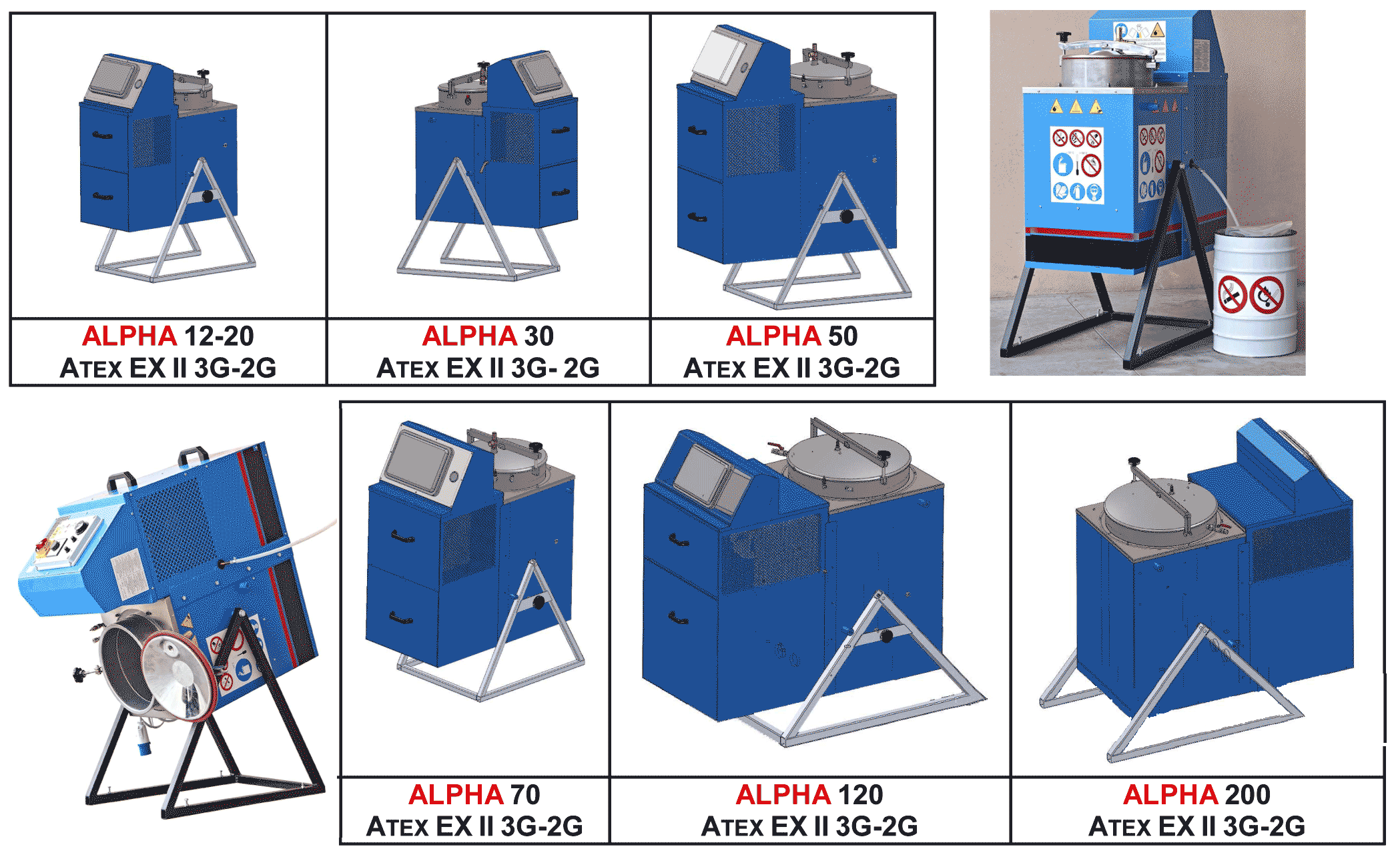

The RANGE OF SMALLER DISTILLATION UNITS with or without mixing systems.

Type of industries

- Paint

- Mechanical

- Printing

- Automotive

- Aeronautical

This small range of distillation units answers to the needs of many industries having limited quantities to recycle.

The work is a “batch” work: the solvent is put in the tank, and the machine start its cycle up to the end of the distillation time (fixed by a timer).

To avoid a lot of maintenance work, solvent can be put in a thermoresistant (up to 180°C ) plastic bag: residue is then staying in this bag and can be easily taken out of the tank without having to clean the walls.

In order to facilitate the evacuation of residues and the maintenance, the distillation tank can tilt

Some interesting accessories are available for this range:

Security: – a kit for nitrocellulose, allowing to avoid any exothermic reaction .

– System allowing to add additive

Vacuum pump

Pumps and tanks allowing to work two cycle on an automatic way

Condenser cooled with cold water

Stainless steel or other protections

A “conveyor”, allowing to distillate simultaneously two not mixable products

About all the range is available in two executions:

– The first is not tilting anymore, but is equipped with a distillation tank on wheels, that can be easily changed by a new one when the distillation cycle is over. Advantage: no need to wait for the cooling of the tank before starting a new cycle.

– the tank is equipped with an internal mixing system, allowing a better distillation, and reducing the residue to the minimum